How to Effectively Test the Physical Properties of Petroleum Coke

Apr 24,2025

1. Introduction to Petroleum Coke Properties

Petroleum coke (petcoke) is a carbonaceous solid derived from oil refining processes. It is a critical material in various industries, particularly in metallurgy and energy production. Understanding its physical properties is paramount for optimizing its use in applications such as aluminum production, cement manufacturing, and as a fuel source. This guide focuses on the effective methods to test these properties and ensure quality.

2. Importance of Testing Petroleum Coke

Testing the physical properties of petroleum coke is essential for several reasons:

- **Quality Assurance**: Ensures the product meets industry standards and specifications.

- **Performance Evaluation**: Helps in assessing how well petcoke will perform in its intended applications.

- **Regulatory Compliance**: Assists in meeting environmental and safety regulations.

- **Cost Efficiency**: Identifying the right grade of petcoke can optimize production costs and improve product quality.

3. Common Testing Methods for Petroleum Coke

Various testing methods are utilized to evaluate the physical properties of petroleum coke. These methods provide crucial insights into its composition and potential performance.

3.1 Density Testing

Density testing is vital in determining the mass-to-volume ratio of petroleum coke. It helps in understanding the packing efficiency of the material, which influences its combustion characteristics.

**Importance**: Knowing the density aids in predicting how the petcoke will behave during handling and processing.3.2 Particle Size Distribution

The particle size distribution (PSD) of petroleum coke significantly affects its reactivity and handling properties.

**Method**: Sieve analysis and laser diffraction techniques are frequently employed to determine PSD. Sieve analysis involves passing petcoke through a series of sieves with different mesh sizes, while laser diffraction measures the scattering of a laser beam through a sample.

**Importance**: A well-defined PSD can optimize combustion efficiency and reduce emissions in industrial applications.3.3 Ash Content Testing

Ash content testing is crucial for understanding the non-combustible minerals present in petroleum coke.

**Method**: The sample is combusted at high temperatures, and the residual ash is weighed. This is typically done using a muffle furnace.

**Importance**: High ash content can negatively impact the performance of petcoke in industrial processes, making this test vital for quality control.3.4 Volatiles Content

Volatiles content refers to the amount of gaseous products released when petcoke is heated.

**Method**: This is often measured using thermogravimetric analysis (TGA), which involves heating the sample in a controlled environment and recording the weight loss.

**Importance**: The volatiles profile can influence combustion characteristics and the overall efficiency of the material in various applications.3.5 Sulfur Content Analysis

Sulfur content is a critical factor as it impacts emissions during combustion.

**Method**: X-ray fluorescence (XRF) or combustion methods can be utilized to accurately determine the sulfur content in petroleum coke.

**Importance**: Reducing sulfur content is essential for meeting environmental regulations and minimizing operational costs in industries that utilize petcoke.4. Advanced Testing Techniques

In addition to common methods, advanced techniques can provide deeper insights into the characteristics of petroleum coke.

- **Scanning Electron Microscopy (SEM)**: Offers detailed images of the surface morphology of petcoke.

- **X-ray Diffraction (XRD)**: Used to identify the crystalline structure of the material, which can affect its performance.

- **Thermal Gravimetric Analysis (TGA)**: Provides information about the thermal stability and composition of petcoke.

These advanced techniques can help in developing a comprehensive understanding of petcoke properties, leading to more informed decisions in its application.5. Recommended Equipment for Testing

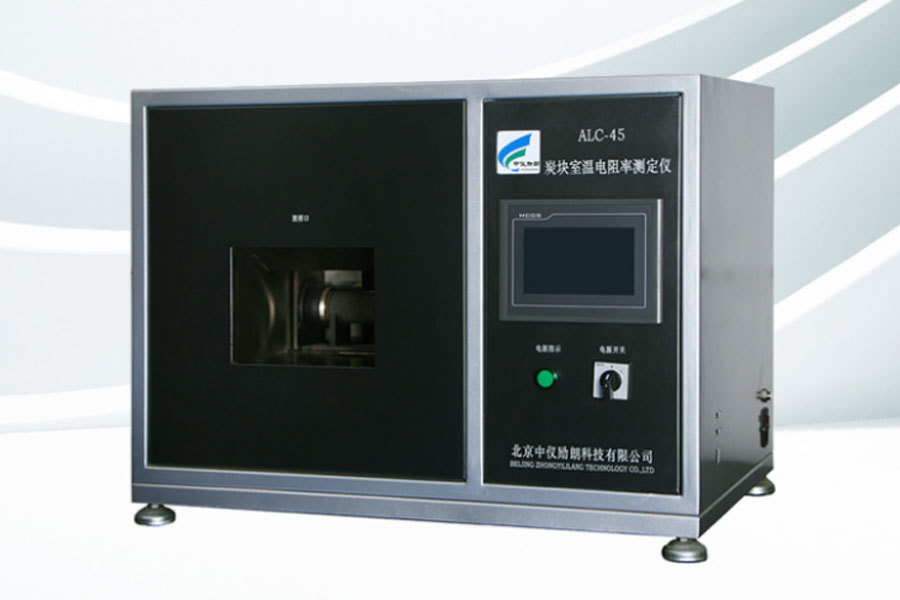

Choosing the right equipment is crucial for effective testing of petroleum coke. Some recommended equipment includes:

- **Density Meters**: For accurate density measurements.

- **Sieves**: Essential for conducting particle size analysis.

- **Muffle Furnaces**: Used for ash content and volatiles testing.

- **XRF Analyzers**: For sulfur and elemental analysis.

- **SEM and TGA devices**: For advanced characterization of material properties.

Investing in high-quality equipment ensures accurate and reliable testing results.6. Quality Control Measures in Testing

Implementing strict quality control measures is essential for maintaining the integrity of test results. Key quality control steps include:

- **Calibration of Instruments**: Regular calibration of testing equipment ensures measurement accuracy.

- **Standard Operating Procedures (SOPs)**: Developing SOPs for each testing method minimizes variability and ensures consistency.

- **Sample Replication**: Testing multiple samples helps in verifying results and identifying anomalies.

Establishing robust quality control measures enhances the reliability of the testing process.7. Case Studies on Petroleum Coke Testing

Real-world applications and case studies can provide valuable insights into the benefits of effective testing. Here are a few notable examples:

- **Case Study 1**: A major aluminum producer implemented rigorous testing protocols for petcoke, resulting in a 15% increase in efficiency in their smelting process due to optimized material selection.

- **Case Study 2**: A cement manufacturing company reduced emissions by 20% after analyzing the ash content and refining their sourcing strategies based on comprehensive testing results.

These case studies highlight the tangible benefits of effective petroleum coke testing in various industries.8. Conclusion

Effectively testing the physical properties of petroleum coke is crucial for ensuring quality and optimizing its application across multiple industries. By employing a range of testing methods, from density and particle size distribution to advanced techniques like SEM and TGA, businesses can gain comprehensive insights into this critical material. Implementing robust quality control measures further enhances the reliability of test outcomes, ensuring that petroleum coke meets the highest standards. As industries continue to evolve, the importance of precise and accurate testing methods will only grow, making this knowledge essential for professionals in the field.9. FAQs

1. What is petroleum coke?

Petroleum coke is a solid carbonaceous material produced from the oil refining process. It is used primarily in industries such as metallurgy and energy production.2. Why is density testing important for petroleum coke?

Density testing helps determine the mass-to-volume ratio of petroleum coke, which impacts its handling, storage, and combustion characteristics.3. What methods are commonly used for testing the sulfur content of petroleum coke?

The sulfur content can be analyzed using X-ray fluorescence (XRF) or combustion methods, providing accurate measurements that are crucial for regulatory compliance.4. How does particle size distribution affect petroleum coke performance?

The particle size distribution influences reactivity, combustion efficiency, and emissions, making it vital for optimizing petroleum coke applications.5. What role does quality control play in testing petroleum coke?

Quality control ensures the reliability and accuracy of test results, minimizing variability and ensuring that the petroleum coke meets industry standards and specifications.

Contact Us