Exploring the Benefits and Applications of a 1700℃ High Temperature Muffle Furnace

Aug 14,2025

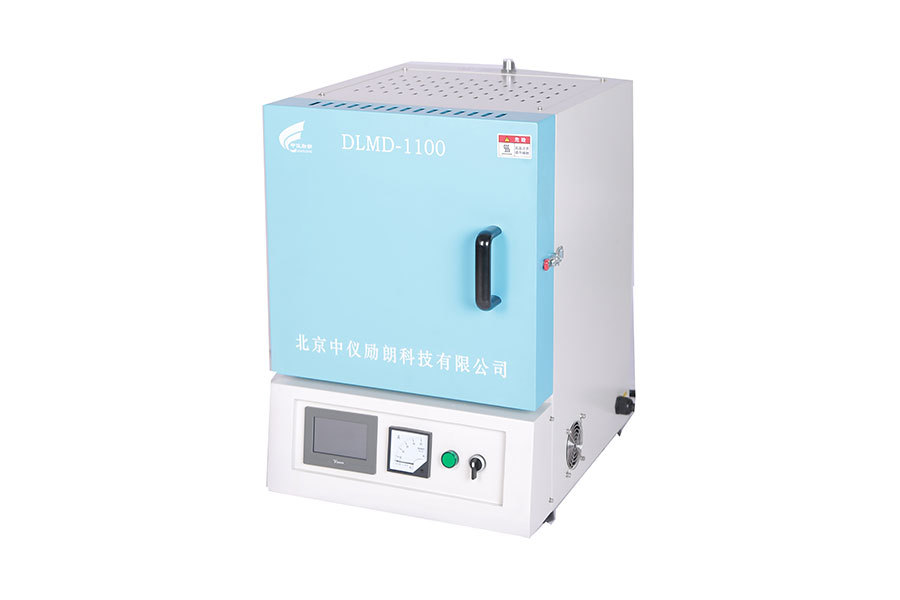

The 1700℃ High Temperature Muffle Furnace is a specialized piece of equipment designed to provide precise thermal processing in a controlled environment. It is widely used in laboratories for applications that require high-temperature heating, such as material testing, ashing, and sintering. The furnace is constructed with advanced insulation materials that allow it to reach and maintain extremely high temperatures efficiently, making it ideal for a range of chemical processes.

One of the key features of the 1700℃ High Temperature Muffle Furnace is its uniform heat distribution. This characteristic is crucial for experiments where consistent temperature control is necessary. Uneven heating can lead to inaccurate results, making this furnace a reliable choice for researchers needing precision. The ability to achieve high temperatures also allows for the melting and fusion of various materials, enabling studies in metallurgy, ceramics, and glass production.

Safety is another important aspect of using a high-temperature muffle furnace. These furnaces are equipped with advanced safety features, such as over-temperature protection and robust thermal insulation, reducing the risk of burns or accidental exposure to high heat. It is essential for users to adhere to safety protocols, including wearing appropriate personal protective equipment (PPE) and ensuring proper ventilation in the working environment.

In addition to its safety and precision, the 1700℃ High Temperature Muffle Furnace is designed for user-friendliness. Many models come with programmable controllers, allowing for easy setting of temperature profiles and monitoring throughout the heating process. This functionality enhances workflow efficiency and enables researchers to focus more on their experiments rather than managing the equipment.

The versatility of the 1700℃ High Temperature Muffle Furnace is evident in its diverse applications. It can be used for ashing organic materials, which is essential in determining the inorganic content of samples. Additionally, it plays a significant role in ceramic and powder metallurgy processes, where precise control over the thermal environment is necessary for successful material transformation.

In summary, the 1700℃ High Temperature Muffle Furnace is an invaluable tool in laboratory settings, particularly within the chemical and material sciences. Its ability to provide high temperatures with uniform heating, combined with safety features and user-friendly controls, makes it an essential asset for researchers. Whether for material testing, ashing, or sintering, this furnace ensures reliable and consistent results, facilitating advancements in various scientific fields.

One of the key features of the 1700℃ High Temperature Muffle Furnace is its uniform heat distribution. This characteristic is crucial for experiments where consistent temperature control is necessary. Uneven heating can lead to inaccurate results, making this furnace a reliable choice for researchers needing precision. The ability to achieve high temperatures also allows for the melting and fusion of various materials, enabling studies in metallurgy, ceramics, and glass production.

Safety is another important aspect of using a high-temperature muffle furnace. These furnaces are equipped with advanced safety features, such as over-temperature protection and robust thermal insulation, reducing the risk of burns or accidental exposure to high heat. It is essential for users to adhere to safety protocols, including wearing appropriate personal protective equipment (PPE) and ensuring proper ventilation in the working environment.

In addition to its safety and precision, the 1700℃ High Temperature Muffle Furnace is designed for user-friendliness. Many models come with programmable controllers, allowing for easy setting of temperature profiles and monitoring throughout the heating process. This functionality enhances workflow efficiency and enables researchers to focus more on their experiments rather than managing the equipment.

The versatility of the 1700℃ High Temperature Muffle Furnace is evident in its diverse applications. It can be used for ashing organic materials, which is essential in determining the inorganic content of samples. Additionally, it plays a significant role in ceramic and powder metallurgy processes, where precise control over the thermal environment is necessary for successful material transformation.

In summary, the 1700℃ High Temperature Muffle Furnace is an invaluable tool in laboratory settings, particularly within the chemical and material sciences. Its ability to provide high temperatures with uniform heating, combined with safety features and user-friendly controls, makes it an essential asset for researchers. Whether for material testing, ashing, or sintering, this furnace ensures reliable and consistent results, facilitating advancements in various scientific fields.

PREVIOUS:

Contact Us