Understanding the Importance of Tar Quinoline Insoluble Matter Testing: A Comprehensive Guide

Oct 03,2025

Understanding the Importance of Tar Quinoline Insoluble Matter Testing

In the world of electrical instruments, where precision and reliability are paramount, understanding the quality of materials used is essential. Tar Quinoline Insoluble Matter Testing is a crucial aspect that helps manufacturers and engineers assess the quality of tar-based products. This article dives deep into the significance of this testing, its methodologies, and how it impacts the electrical industry.

What is Tar Quinoline Insoluble Matter?

Tar Quinoline Insoluble Matter (TQIM) refers to the residue left after the distillation of tar, particularly in the production of carbon black and other electrical materials. This matter mainly contains complex organic compounds that can significantly influence the physical and chemical properties of the final product.

The Composition of Tar Quinoline Insoluble Matter

TQIM is primarily composed of complex hydrocarbons, heteroatoms including nitrogen, sulfur, and oxygen, which can affect various properties such as conductivity, thermal stability, and resistance to environmental factors. Understanding its composition is vital for manufacturers aiming to produce high-quality electrical instruments that meet stringent industry standards.

Why is Tar Quinoline Insoluble Matter Testing Important?

Testing for TQIM is essential for several reasons:

1. Ensuring Material Quality

Quality assurance is critical in the manufacturing of electrical instruments. By testing for TQIM, manufacturers can ensure that their raw materials meet the specified standards, leading to products that are reliable and durable in the field.

2. Compliance with Industry Standards

Many industries, particularly those involved in electrical engineering, have stringent standards regarding the materials used. TQIM testing helps ensure compliance with these regulations, reducing the risk of penalties or product recalls.

3. Enhancing Product Performance

The presence of high levels of TQIM can negatively impact the performance of electrical instruments. By monitoring and controlling the levels of TQIM, manufacturers can enhance the overall functionality and lifespan of their products.

4. Minimizing Environmental Impact

Tar-based products can have a significant environmental impact if not managed properly. By conducting TQIM testing, companies can make informed decisions about waste management and environmental compliance.

Methodologies for Tar Quinoline Insoluble Matter Testing

Various methods are available for testing TQIM, each with its advantages and disadvantages. Understanding these methodologies is crucial for selecting the right testing approach for your specific needs.

1. Gravimetric Analysis

Gravimetric analysis is one of the most common methods for determining TQIM. This technique involves dissolving a sample in a solvent, filtering out insoluble matter, and weighing the residue. This method is known for its accuracy and reliability.

Steps Involved in Gravimetric Analysis

- **Sample Preparation**: The sample is accurately weighed and prepared for solvation.

- **Dissolution**: The sample is dissolved in a suitable solvent.

- **Filtration**: The solution is filtered to separate the insoluble matter.

- **Drying**: The residue is dried to a constant weight.

- **Calculation**: The TQIM percentage is calculated based on the initial sample weight.

2. Spectroscopic Methods

Spectroscopic techniques, such as Infrared (IR) and Nuclear Magnetic Resonance (NMR) spectroscopy, can also be employed for TQIM analysis. These methods offer insights into the molecular structure of the insoluble matter, providing valuable information about its chemical properties.

3. Chromatographic Techniques

Chromatography, including High-Performance Liquid Chromatography (HPLC), can separate and quantify various components within the TQIM. This method is highly effective for detailed analysis but requires specialized equipment and expertise.

Interpreting Tar Quinoline Insoluble Matter Test Results

Understanding the results of TQIM testing is vital for decision-making in manufacturing processes.

1. Acceptable Limits of TQIM

Manufacturers must be aware of the acceptable limits of TQIM for their specific applications. These limits can vary depending on industry standards and product requirements.

2. Implications of High TQIM Levels

High levels of TQIM can lead to several issues, including reduced electrical conductivity, increased thermal resistance, and potential compliance violations. Understanding these implications can help manufacturers take corrective actions proactively.

Case Studies: Impact of TQIM Testing in the Electrical Industry

Examining real-world applications of TQIM testing can provide valuable insights into its importance.

1. Case Study: Quality Control in Carbon Black Manufacturing

In the production of carbon black, a critical material used in the electrical industry, regular TQIM testing has led to significant improvements in product quality and consistency. By adhering to strict TQIM limits, manufacturers have successfully enhanced the performance of their final products.

2. Case Study: Compliance and Regulatory Success

A leading electrical instrument manufacturer faced compliance issues due to high levels of TQIM in their raw materials. By implementing regular TQIM testing and adjusting their sourcing strategies, they were able to meet industry standards and avoid costly penalties.

Best Practices for Implementing TQIM Testing in Manufacturing

Integrating TQIM testing into the manufacturing process can be streamlined with the following best practices:

1. Regular Training for Staff

Ensuring that staff members are well-trained in TQIM testing methodologies will help maintain high standards of quality control.

2. Establishing Standard Operating Procedures (SOPs)

Creating SOPs for TQIM testing can enhance consistency and reliability in test results, ultimately leading to improved product quality.

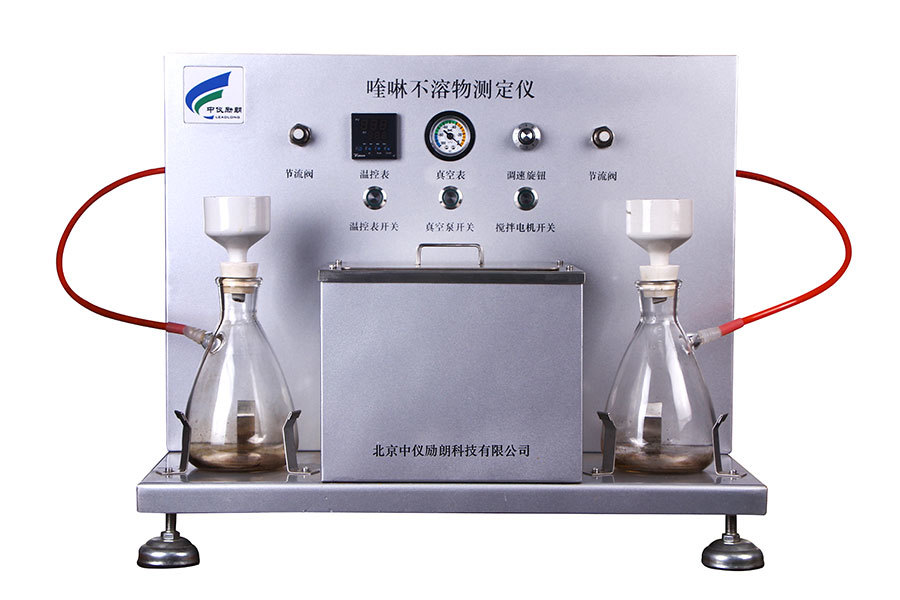

3. Investing in Advanced Testing Equipment

Upgrading to state-of-the-art testing equipment can enhance the accuracy and efficiency of TQIM testing, helping manufacturers stay ahead in a competitive market.

Frequently Asked Questions (FAQs)

1. What is the significance of Tar Quinoline Insoluble Matter Testing?

TQIM testing is crucial for ensuring the quality and compliance of electrical materials, leading to better product performance and reduced environmental impact.

2. How often should TQIM testing be conducted?

The frequency of TQIM testing depends on the production rate and the variability of raw materials. Regular testing is recommended to maintain quality standards.

3. What are the accepted limits for TQIM in electrical materials?

Accepted limits for TQIM can vary based on industry regulations and specific product requirements. Manufacturers should consult relevant standards for guidance.

4. Are there alternative testing methods for TQIM?

Yes, alternative methods such as spectroscopic and chromatographic techniques can be employed, although gravimetric analysis is the most common.

5. How can high TQIM levels affect product performance?

High TQIM levels can lead to reduced electrical conductivity, increased thermal resistance, and compliance issues, potentially affecting the performance and reliability of electrical instruments.

Conclusion

Understanding and implementing Tar Quinoline Insoluble Matter Testing is essential for manufacturers in the electrical industry. By ensuring material quality, complying with industry standards, and enhancing product performance, companies can maintain a competitive edge while minimizing environmental impact. Regular testing, coupled with best practices, can lead to improved product reliability and customer satisfaction. As the industry continues to evolve, staying informed about TQIM testing methodologies and implications will be crucial for ongoing success in the electrical sector.

Contact Us