Enhancing Electrical Performance: The Significance of Petroleum Coke Quality Testing

Oct 09,2025

Enhancing Electrical Performance: The Significance of Petroleum Coke Quality Testing

Table of Contents

- Introduction to Petroleum Coke in Electrical Applications

- Understanding Petroleum Coke Quality Testing

- The Importance of Quality Testing for Petroleum Coke

- Testing Methodologies in Petroleum Coke Quality Assessment

- Benefits of Quality Testing in Electrical Performance

- Industry Standards for Petroleum Coke Quality Testing

- Real-World Applications of Quality Testing

- Future Trends in Petroleum Coke Quality Testing

- Conclusion

- Frequently Asked Questions

Introduction to Petroleum Coke in Electrical Applications

Petroleum coke, often referred to as petcoke, has emerged as a vital material in the electrical and energy sectors. This carbonaceous solid is derived from oil refining and serves as a key component in producing electrodes for aluminum smelting and various other electrical applications. Understanding the significance of **petroleum coke quality testing** is crucial for enhancing electrical performance, ensuring safety, and improving efficiency in industrial operations.

When employed correctly, petroleum coke can substantially improve the conductivity and overall performance of electrical components. However, the inherent variability in the quality of this material can lead to performance discrepancies. Hence, implementing rigorous quality assessment methodologies is essential for manufacturers and engineers alike.

Understanding Petroleum Coke Quality Testing

Quality testing for petroleum coke involves a series of analytical procedures designed to evaluate its physical and chemical properties. These tests are pivotal for ensuring that the material meets specific performance standards required for various electrical applications. The quality of petroleum coke is influenced by multiple factors, including its purity, elemental composition, and ash content, all of which directly affect its performance in electrical systems.

Standard quality tests include assessments of **volatiles, moisture content, ash content**, and **sulfur levels**. Each of these parameters plays a crucial role in determining the suitability of petroleum coke for specific applications.

The Types of Quality Tests for Petroleum Coke

- **Elemental Analysis:** Involves evaluating the chemical composition, including carbon, hydrogen, nitrogen, and sulfur content.

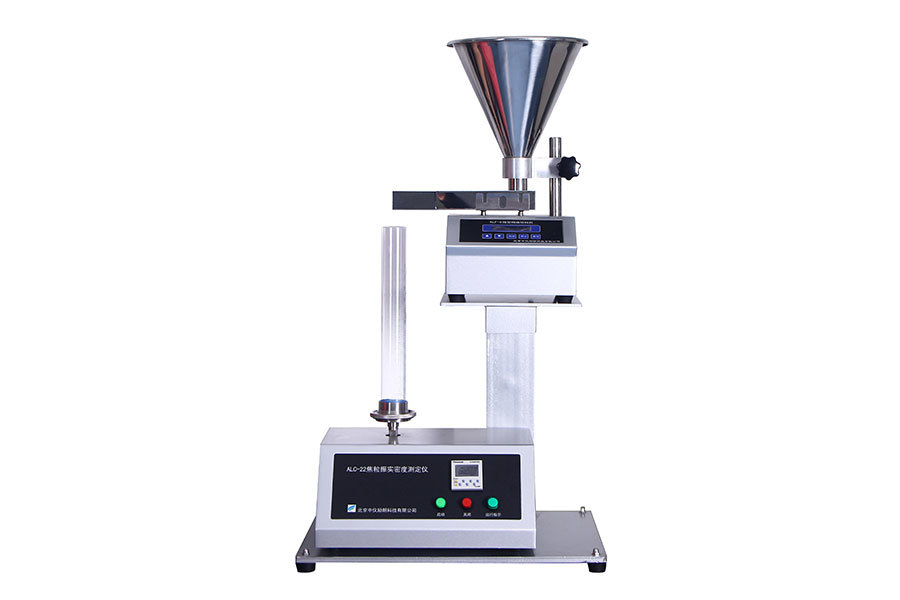

- **Physical Properties Testing:** Assessing particle size distribution, density, and porosity.

- **Thermal Analysis:** Measuring the material's behavior under high temperatures to determine its thermal stability.

- **Electrical Conductivity Tests:** Evaluating how well the material conducts electricity, which is essential for its use in electrical applications.

The Importance of Quality Testing for Petroleum Coke

Quality testing is not merely an administrative requirement; it is a critical process that ensures the **performance and reliability** of electrical systems. The significance of this testing can be understood through several key aspects:

1. Enhancing Performance and Efficiency

High-quality petroleum coke contributes to improved conductivity and lower resistance in electrical applications. By ensuring that the coke used is of superior quality, manufacturers can enhance the overall **efficiency** of their electrical systems.

2. Reducing Operational Risks

Using substandard petroleum coke can lead to catastrophic failures in electrical systems, resulting in downtime and costly repairs. Quality testing mitigates this risk by identifying potential issues before they escalate.

3. Compliance with Industry Standards

Incorporating quality testing aligns with industry regulations and standards, ensuring that manufacturers meet the required specifications for electrical materials. Compliance not only guarantees safety but also enhances the brand's reputation.

Testing Methodologies in Petroleum Coke Quality Assessment

Various methodologies are employed in the quality testing of petroleum coke to ensure accuracy and reliability. These methodologies include:

1. Laboratory Testing

Laboratory testing involves several analytical techniques that provide detailed insights into the material's properties. These tests are fundamental for quality assurance before the material is utilized in electrical applications.

2. On-Site Testing

On-site testing can be conducted to evaluate the performance of petroleum coke in real-world scenarios. This method provides practical insights into how the material will perform under operational conditions.

3. Continuous Monitoring

Implementing continuous monitoring systems ensures that the quality of petroleum coke remains consistent throughout the production process, reducing the likelihood of variations that could impact electrical performance.

Benefits of Quality Testing in Electrical Performance

The benefits of conducting quality tests on petroleum coke extend beyond mere compliance. Here are several advantages that underscore the importance of these assessments:

1. Improved Product Quality

Quality testing helps identify and eliminate impurities, ensuring that the final product meets the highest standards of quality.

2. Enhanced Customer Satisfaction

By providing high-performance materials, manufacturers can significantly enhance customer satisfaction, leading to stronger business relationships and increased repeat business.

3. Cost Savings

Investing in quality testing can save companies money in the long run by preventing costly failures and extending the lifespan of electrical components.

Industry Standards for Petroleum Coke Quality Testing

Adhering to industry standards is paramount for ensuring the quality and safety of petroleum coke. Various organizations, such as ASTM International, provide guidelines and standard practices for testing petroleum coke.

1. ASTM D5003

This standard outlines the method for determining the physical and chemical properties of petroleum coke, ensuring that it meets industry requirements.

2. ISO Standards

The International Organization for Standardization sets guidelines that help manufacturers maintain quality control over their products, including petroleum coke.

Real-World Applications of Quality Testing

Quality testing for petroleum coke is applied across various industries, showcasing its versatility and significance. Here are some of the key applications:

1. Aluminum Production

In the aluminum industry, petroleum coke is used in the manufacture of electrodes. Quality testing ensures that the electrodes perform optimally, which is crucial for the efficiency of the smelting process.

2. Electrical Power Generation

Quality petroleum coke plays an essential role in generating electrical power, particularly in coal replacement applications. Testing guarantees that it meets the necessary specifications for combustion.

3. Steel Manufacturing

Steel manufacturers employ petroleum coke in the production process. Ensuring quality through testing helps maintain the structural integrity and performance of the final product.

Future Trends in Petroleum Coke Quality Testing

As technology continues to advance, so do the methodologies and practices surrounding petroleum coke quality testing. Anticipated trends include:

1. Increased Automation

Automation in testing processes can enhance speed and accuracy, allowing for more extensive and detailed quality assessments.

2. Adoption of AI and Machine Learning

Artificial Intelligence and machine learning algorithms can analyze large data sets from quality tests to predict potential quality issues before they arise.

3. Sustainability Focus

As industries shift toward more sustainable practices, quality testing will also evolve to emphasize environmental impacts, ensuring that petroleum coke production aligns with sustainability goals.

Conclusion

The significance of petroleum coke quality testing cannot be overstated. It is a vital component in ensuring the electrical performance, efficiency, and reliability of various materials across multiple industries. By understanding the methodologies involved and the benefits of robust quality assessment, manufacturers and engineers can leverage petroleum coke to enhance their operations significantly. As the industry advances, keeping abreast of new testing methodologies and standards will be crucial for maintaining a competitive edge in the market.

Frequently Asked Questions

What is petroleum coke, and why is it important in electrical applications?

Petroleum coke is a carbon-rich solid produced from oil refining. It is important in electrical applications due to its use in manufacturing electrodes and its ability to improve conductivity.

How is petroleum coke quality tested?

Quality testing involves several methodologies, including elemental analysis, physical properties testing, thermal analysis, and electrical conductivity tests.

What are the key benefits of petroleum coke quality testing?

Key benefits include improved product quality, enhanced customer satisfaction, and cost savings through reduced operational risks and longer equipment lifespan.

What industry standards govern petroleum coke quality testing?

ASTM D5003 and various ISO standards provide guidelines for assessing the quality of petroleum coke to ensure compliance with industry requirements.

How does quality testing impact the aluminum production process?

In aluminum production, quality testing ensures that the petroleum coke used for electrodes meets performance standards, which is critical for the efficiency and effectiveness of the smelting process.

PREVIOUS:

Contact Us