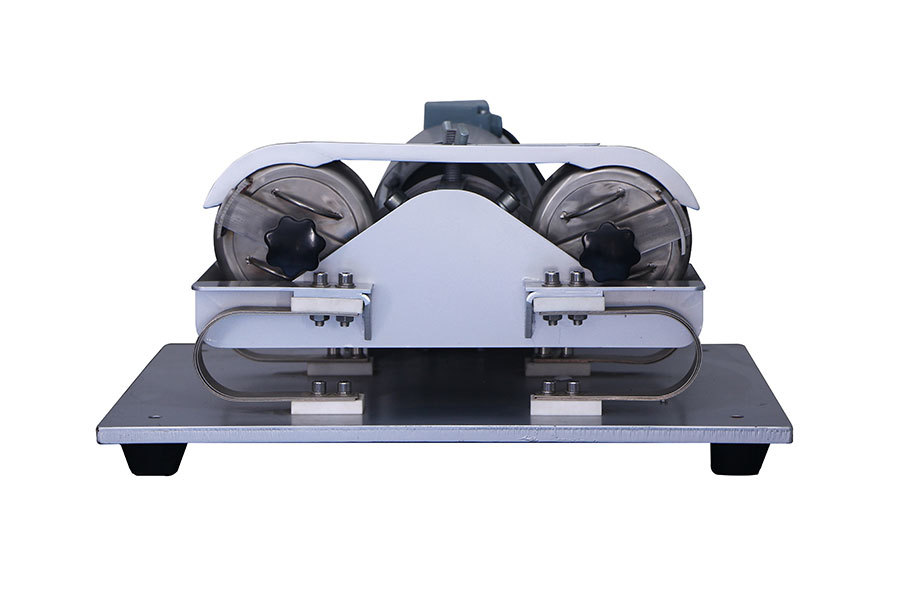

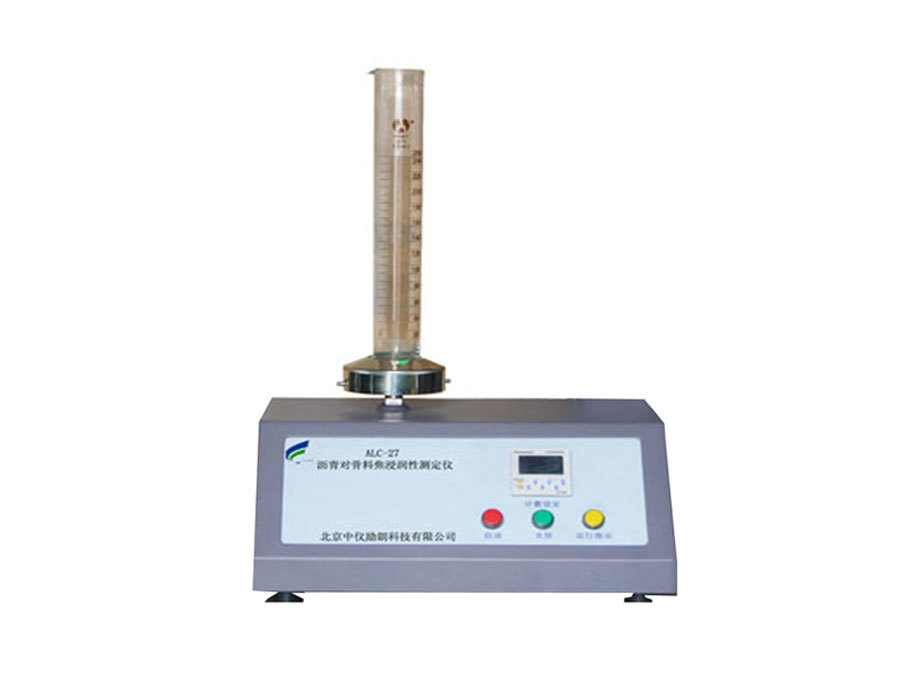

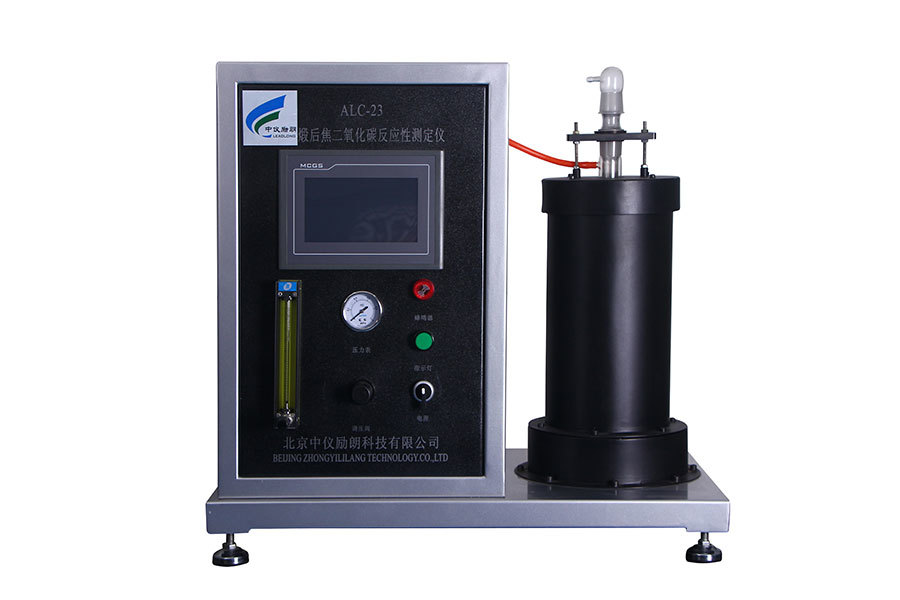

The ALC-22 Tap Volume Density Tester is used to measure the tap volume density of petroleum coke particles, coke particles, and other non-viscous particles under certain vibration forces and vibration times. Tap Volume Density Tester is a high-performance testing equipment specially used for the analysis of the vibration characteristics of powder materials. It is suitable for the accurate measurement of various types of metal powders, non-metallic powders, carbonaceous materials, etc. The equipment controls the vibration compaction process of the powder sample in the standard measuring cylinder, obtains the volume of the sample in the vibrated state, and calculates its vibrated volume density based on this, providing an important basis for material formulation design, quality control, and process improvement.

The whole machine has a reasonable structure and adopts a high-precision electromagnetic vibration system, which can achieve uniform and stable tapping movement, ensure the consistency of the vibration effect, and the test results are highly repeatable. The instrument is equipped with an intelligent control panel, and users can flexibly set the number and frequency of vibrations to adapt to different standards and test requirements. The operation interface is simple and intuitive, and the test process is highly automated, which significantly improves the experimental efficiency and accuracy.

Instrument characteristics: This product meets the requirements of ISO10236, YS/T587.10- 2006.

1、The micro vibrating feeder synchronizes precise feeding.

2、Accurate control of amplitude and vibration force.

3、 Set the number of vibrations and stop automatically after vibration.

4、The measuring cylinder is precise to 1 ml. The elastic clamping cover design ensures that the measuring cylinder is in close contact with the base during the vibration process.

The Tap Volume Density Tester has multiple international general test standards and is suitable for long-term use in laboratories, production workshops , and R&D institutions. The materials are made of high-quality alloys and engineering plastics, which have good wear resistance and corrosion resistance, and extend the service life of the equipment. A variety of measuring cylinders and fixtures are available to meet the test requirements of different powder forms and sample capacities. Through scientific testing methods and reliable data output, the tapped bulk density tester can fully reflect the stacking performance of powder materials, providing strong support for improving product consistency and promoting process optimization.

Technical parameters:

| Model | ALC-22 |

| Bracket amplitude | 3mm±0.1mm |

| Total mass of bracket | 350g ± 5g |

| Vibration frequency | 250 ±15 times/min |

| Vibration frequency | 1500 times |

| Barrel volume | 250ml |

| Barrel mass | 290 g ± 5 g |

| Feeding mode | Feeding with micro vibrating feeder |

| Feeding accuracy | 10g/min |

| Time control accuracy | ±0.2s |

| Motor power | 0.18KW Power voltage |

| Equipment weight | 32kg |

| Installation Size | 450 x 340 x 700mm |

Keywords

Tap Volume Density Tester

Tap Volume Density Tester

Contact Us

Classification